Drilling

This morning started with one of our locals coming up to the house about an hour before we were suppose to meet him down at the radio station. And since they are usually at least a half an hour behind we knew something was up. I waited for him to explain to April what he need and then for her to translate it back to us. He said that they need some help down at the lot we had helped clear brush on earlier in the week. Something about moving stuff and a machine but she didn’t really know. They needed two guys to go and help the pastor and another guy with this stuff. And the pastor was on his way to pick us up and would be here any minute. Tyson and I offered to go having no idea what we where getting into and without having had breakfast yet. So we threw on some work clothes and grabbed a quick bite to eat and we were off. We jumped in the back of the pastors pickup and he headed toward the lot. Just before we got to the lot he turned off in the opposite direction of it. We drove through a neighborhood and came to a house where we knocked on the front gait. We went in and they started handing us stuff to load in the truck. Some tools, some big homemade brackets, some rope, a bunch of meter long pieces of pipe, a gear box.

At that point, we are really starting to wonder what we would be doing. A small differential out of car or truck, a gear reduction box, and then I saw it, what looked like a large homemade drill bit on the end of an inch and a quarter piece of pipe. So asked Roberto in my very broken Spanish are we are drilling a well? He replies in his better English that yes we are drilling a well with this machine that he invented and built. I got totally excited, not only have I never drilled a well but I would get to see this machine that he has made out of common stuff that you can find almost anywhere. This is totally my kind of thing. We loaded a small Brigs and Straten engine and a few more miscellaneous parts and we were off. We arrived at the lot and began unloading the stuff, and as we went we noticed that one of the parts was broken, so we finished unloading everything else and the broken part was off to the welder. When we pulled up to the welding shop I could see that it is very small, small enough that I wonder if he even has room for a real welder inside. We started preparing the metal for welding. The young man at the shop went inside and brought out a small welder about the size of a couple shoe boxes. Like one you would buy at a small parts store or Harbor Freight. And, its an arc welder not a wire-feed or anything like you would usually see back in the States. He hooked it up and went to to town welding the piece back on and reinforcing the other one so they hopefully would stay in place. We paid him Q25 which is about 3 dollars for a half and hours work. And it was back to the lot. We arrived and started prepping the site where we were to drill. We did holes to help filter out the mud from the water as is comes back up to the surface from the bottom of the hole, we made a flat spot for the base of our machine, piped in water from the other side of the property, which took three trips to the hardware store to get all the pieces for. We assembled and erected the rig and attached guy lines to keep it level and upright. We mounted the Subaru differential and the 30:1 gear box and attached them to one another with the drive chain. We started to mount the small lawnmower type engine on top of the gear reduction box but the centripetal clutch had a spring that had been stretched out, so it wouldn’t go back together. They went and found several springs that had potential to work and made one work. We got the engine on and everything was ready to go except that a part that gets the water into the inside of the pipe but still allows the pipe to spin and the water hose to stay still was totally seized up and couldn’t spin. So we decided to call it at day.

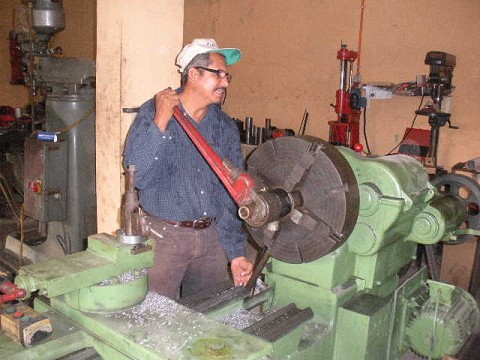

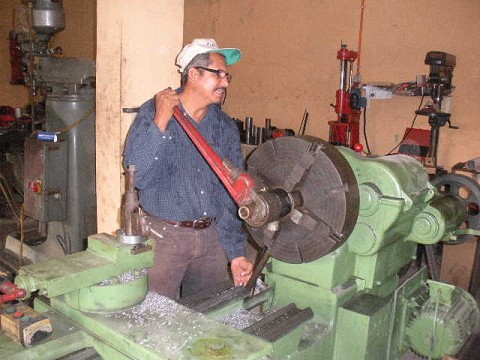

We got going early the next morning and went down to the lot to get started. The part was still at the machine shop so Roberto and I went down to see how it was coming. It was, of course, not coming. The part was still laying on the floor where it was left the day before. We got them to start working on it. We chucked the entire part up in to a huge lath and got at big pipe wrench and were just able to get it to turn. After a few more rotations by hand we tuned on the lath and let it spin the unit while the wrench held the shaft. That took care of that but we also had to get the broken end of the old water supply pipe out of the unit and since we are in Guatemala and they don’t seam to have pipe easy-outs here it turned into an hour job. And while we are at it we figured we might as well build a bracket to protect the pipe so it won’t break again. That all being taken care of and our early start, shot we get back to the lot around 10. We put it all together and finally we are able to begin drilling! Yay!

One thing that is great about Guatemala is that they are so much more laid back here. After an entire day’s worth of finding and fixing broken parts and problems, most people in the states would be really frustrated with how the job is going. But here we just expect it and it really doesn’t seem to bother anyone. We continued drilling until around noon, when the pastor’s wife and family all showed up with an amazing lunch for us. We stopped and ate for a bit and then went back to drilling.

We drilled down about four feet at a time and then we had to stop and add another section of pipe and then we can keep drilling. We reached about 90 to 100ft and the drilling started to get harder. And the pump blew a seal, which was no surprise, it has been pumping a thick mix of mud and water that would sit on the ground almost an inch thick without flowing away. The thickness helped keep the walls of the hole from collapsing and also moved the chunks of mud up away from the drill head and back to the surface. But it was defiantly not doing the pump seals any favors on the way by. Shortly thereafter the clutch started to skip and make noises that a clutch should’t make. We continued on for a little bit because we were so close, we only had three more lengths of pipe to go, but finally we decided that this was starting to get to hot and we didn’t want to create any more problems. So we stopped and sent one of the guys for pump parts. As we were waiting we open up the clutch to see what was going on, the new spring we made work had broken. We make another spring and the guy arrived with the new pump parts. But none of them fit, some were too big and some too small, so we called it a day and headed back to Casa Verde, our home this month. But not before Roberto asked me to speak at his church later that night….